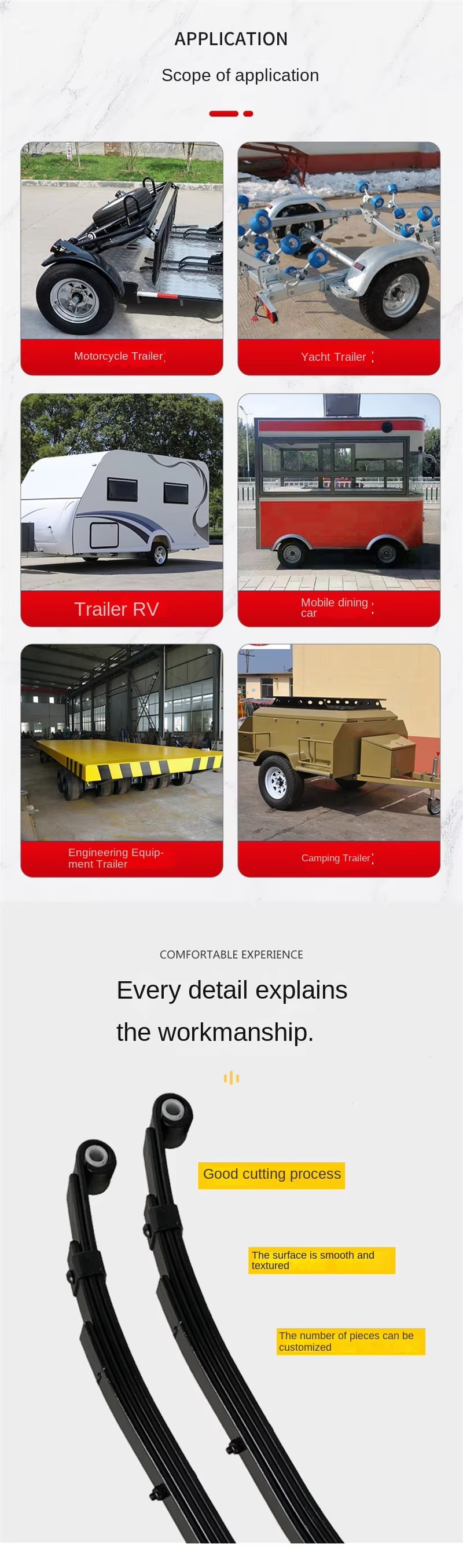

Leaf Springs for Trailer Truck Leaf Spring

Leaf springs, also known as flat springs, are a type of automotive suspension system that has been around for centuries and continues to play a crucial role in various applications due to their simplicity, durability, and load - bearing capabilities.

A leaf spring primarily consists of a stack of flat, curved metal leaves, usually made of high - strength steel. The longest leaf at the bottom is called the main leaf, which has a semi - circular shape. Successive leaves above it are progressively shorter. These leaves are held together by a center bolt that passes through holes in the middle of each leaf, ensuring they work in unison. Additionally, U - bolts are used to secure the leaf spring to the vehicle's axle. The curvature of the leaves gives the spring its initial tension and allows it to flex under load.

When a load is applied to the vehicle or the structure supported by the leaf spring, the leaves flex. As the weight increases, the spring compresses, and the leaves flatten out slightly. This compression stores mechanical energy within the spring. When the load decreases, the stored energy causes the leaves to return to their original curved shape, providing a rebound force. The multiple layers of leaves work together to distribute the load evenly across the spring, enhancing its strength and ability to absorb shocks and vibrations.

We offer customized service

Please kindly contact us,we will be happy to answer you very soon.

Cell/Whatsapp:+86 15259294925

Email:ellaspring@yeah.net

Categories

Contact Us

- +86-15259294925

- +86-15259294925

- ellaspring@yeah.net

- +86-15259294925